Log houses

PRODUCTION PHASES OF LOG HOUSE COMPONENTS

The houses are manufactured from spruce flat-on-flat solid logs with a thickness of 60 mm, 70 mm, 95 mm, and glued logs 110 mm, 140 mm, 160 mm, 180 mm, 200 mm and 240 mm thick.

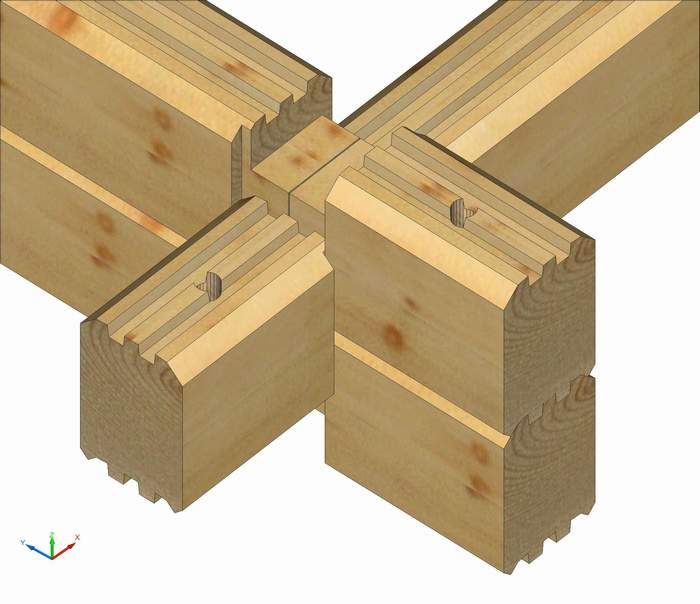

The logs are planed on four sides with edge chamfers, and milled to obtain double tongues and grooves that provide additional sealing along the horizontal log joint. Wall corners are cut to form interlocked joints, with quoin ends protruding 15 cm from the facade contour. Wood used to manufacture our houses is purchased in Scandinavia. It is spruce characterized by a 16% humidity. External walls of all-year-round houses are fitted with additional internal wind insulation made from vapour-permeable membrane and mineral-wool insulation with a thickness of 15 cm. The walls are then finished from the inside with panelling imitating planed logs with a thickness of 18 mm or using 12 mm plasterboards + 12 mm OSB.

The components of flat-on-flat log walls are prepared by the wooden component production division. Supplied Swedish plank is initially prepared for milling by gluing to the desired length with comb joints and to the desired thickness using hydraulic presses, in line with the specifications. The plank is then transferred to a four-side planer where a flat log is obtained with 2 tongues and grooves. The material so prepared is transported to a machine designed to cut components of walls, ceiling beams and roof structures in line with a file provided by the designer.

Once cut, the covered components (invisible after assembly, e.g. roof structure) are transported to a bath where they are immersed in an impregnating agent (protecting against fungi and insects). The wooden component production division also manufactures panelling for internal wall finishing, eaves overhangs, flooring, joists, wooden structures, battens and rafters, finishing slats, frames for openings, stairs, beam finishing slats, quarter sawn elements, angle sections, slats mounted under gutters, wooden laces. Plank for floors and panelling is additionally dried in the drying room to 11% humidity.

The carpentry division manufactures windows and doors for ordered houses. External window components and entrance doors are manufactured from glued pine wood. Window pane and door frames are milled to dimensions consistent with the statement included in the detailed building design, then joined using carpenter’s glue and pressed until dry. Another phase includes painting of windows and doors using water-based lacquers for wood. Once the lacquer coating is dry, 4/18/4 framed insulating glass panes filled with argon are mounted. The following phase in the window production process includes installation of perimeter tilt-and-turn mechanisms, hinges, seals and handles. Complete windows and doors are protected against dust and damage by plastic film. They are then stored in a warehouse until their shipment date. Tatra-House also manufactures interior doors made from solid spruce plank finished with veneer.